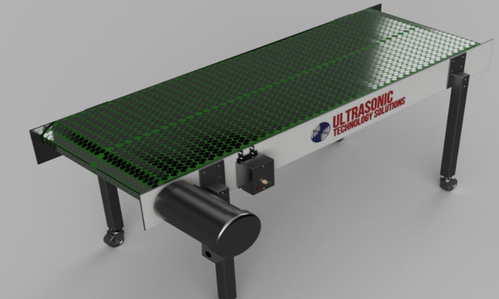

Direct Contact Ultrasonic Drying!

Energy Consumed by dryers accounts for >15% of the energy used in USA = 1.1% of U.S. GDP.

Conventional dryers use heat to evaporate water and dry wet articles. Evaporation of water is a very energy-intensive process that requires about 2200 kJ/kg (0.611 kWh/kg) of energy. Considering the thermal losses in the typical dryer, even more, energy is used for drying.

In 2014, Dr. Momen, the founder of Ultrasonic Technology Solutions, and the team invented the direct contact ultrasonic drying technology at Oak Ridge National Laboratory.

In this novel approach, instead of using heat, the high-frequency vibration of piezoelectric transducers is used to remove the water from the article.

During this process, the water leaves the wet article in the form of cold mist that can be carried out with the airstream or reclaimed within the device.

Our process is upto 5 times more efficient and 2 times faster than the conventional heat-based dryers. Notably, it excels even further with thicker products.

What are the potential benefits?

Energy Cost Savings:

Drying energy in North America is responsible for ~ 15% of the country's energy consumption. This is equivalent to tens of billion dollars in energy bills annually. In many applications, our ultrasonic drying technology could significantly cut energy consumption and energy bills.

Improved Productivity:

In many cases, ultrasonic drying is much faster than conventional heat-based drying and can improve the productivity of the plant.

Improved Drying Quality:

Ultrasonic drying does not use heat, which offers an attractive option for drying heat-sensitive material such as food products or energy-intensive products.

Drying energy in North America is responsible for ~ 15% of the country's energy consumption. This is equivalent to tens of billion dollars in energy bills annually. In many applications, our ultrasonic drying technology could significantly cut energy consumption and energy bills.

Improved Productivity:

In many cases, ultrasonic drying is much faster than conventional heat-based drying and can improve the productivity of the plant.

Improved Drying Quality:

Ultrasonic drying does not use heat, which offers an attractive option for drying heat-sensitive material such as food products or energy-intensive products.